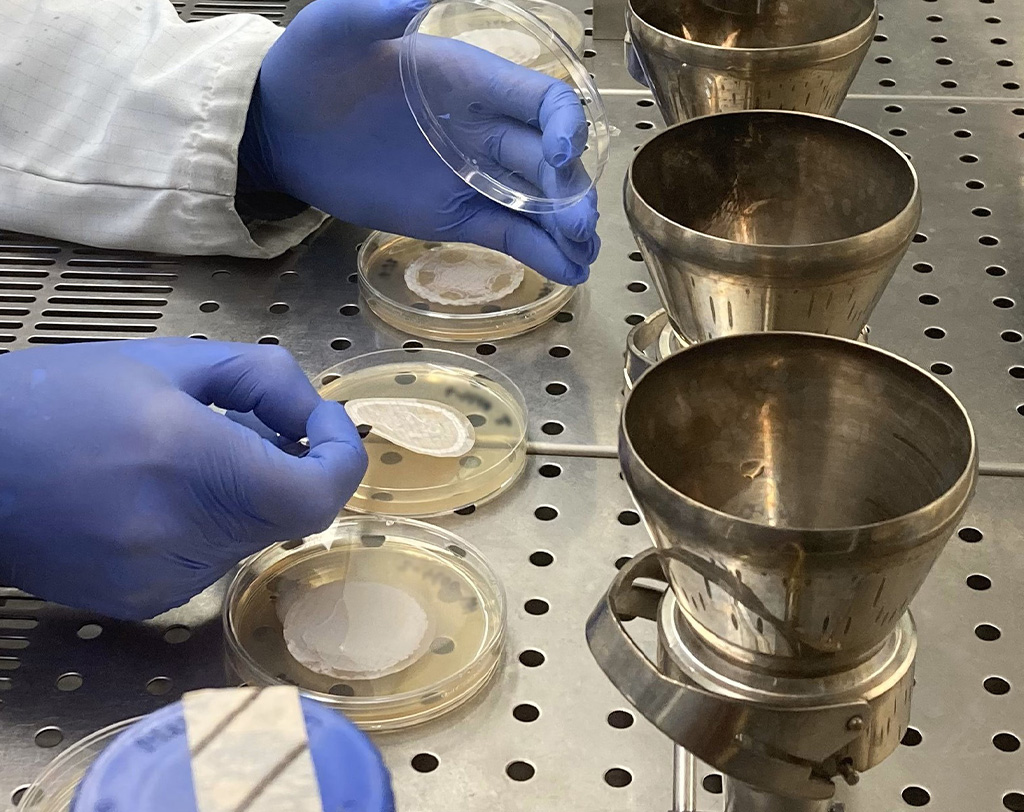

Mineral Oil Analysis, Fuel Testing, Combustion Testing. Your Added Value.

Our services offer clear advantages:

- Standards-compliant testing

We support you in complying with relevant standards such as EN 228, EN 590, EN 14214, EN 15376, as well as applicable national fuel and fuel labeling regulations. - Fast results

Thanks to our state-of-the-art laboratories, you receive precise analyses in the shortest possible time. - Consulting and support

Our experts help you optimize your processes and comply with legal requirements. - Long-term partnerships

With over 30 years of experience, we are a reliable partner for your quality assurance.

Contact us

Are you interested in our mineral oil analysis services? Whether for quality assurance during storage, assistance after issues (e.g. customer complaints), sampling, or fuel testing for emergency generators – our team offers extensive expertise. Contact us today to receive a customized offer to ensure the quality of your products. Click here to find your regional contact.

Our Analytical Services

We are also happy to assist you personally. Here you can find your regional contact.

Testing Methods

-

161 KB

-

152 KB

-

144 KB

-

147 KB

-

143 KB

-

156 KB

-

136 KB

Petrol according to EN 228

Petrol consists of a mixture of different hydrocarbons with boiling points between 30 and 210°C and may contain oxygenated compounds such as alcohols and ethers.

Diesel fuels according to EN 590

Diesel fuels are mixtures of various hydrocarbons with boiling ranges between 180 and 360°C. In some countries, the biodiesel content is limited to 7%.

HVO according to EN 15940

HVO (Hydrotreated Vegetable Oil)

is a hydrocarbon produced via catalytic hydrogenation

of vegetable oils.

Ethanol according to EN 15376

Ethanol is used as a blending component in petrol fuels.

Biodiesel (FAME) according to EN 14214

Biodiesel or fatty acid methyl esters (FAME) are produced by transesterifying vegetable oils or animal fats, including used cooking oils.

Light heating oil (HEL)

A hydrocarbon mixture with boiling points between 180 and 360°C, which in some regions must be dyed red and contain an additional marker substance.

Residual heating oils

(Light and heavy heating oils) are hydrocarbon mixtures containing fractions from the vacuum distillation of crude oil.

NOX reduction agents according to ISO 22241-1

Aqueous urea solutions used to reduce nitrogen oxide emissions, such as AdBlue.

Pyrolysis oils

Pyrolysis oils are distillate fractions obtained, for example, from the thermal decomposition of plastics or wood.

Glycerine

Glycerine is produced, for example, during biodiesel production.

Contact

Contact

Contact

Contact Career

Career