Blackout – A Realistic Risk in Europe?

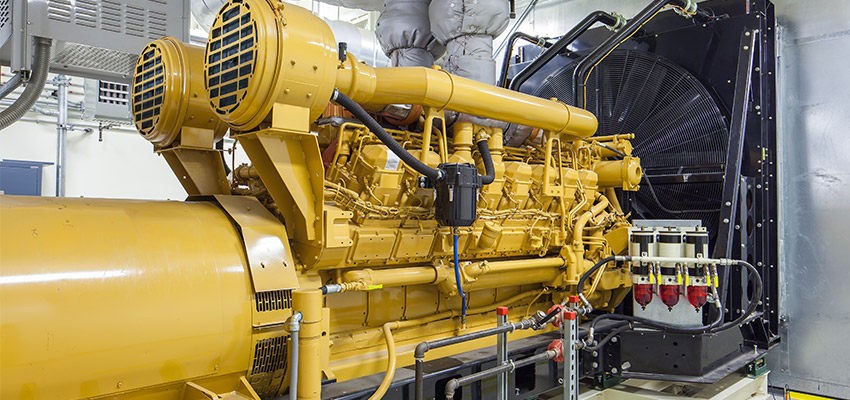

The large-scale power outage in Chile on 26 February 2025 highlights the vulnerability of modern infrastructures. In Germany and Austria, regional blackouts can also occur due to natural disasters, grid overloads, or cyberattacks. Critical infrastructures such as hospitals, water supply, telecommunications, and traffic control rely on a functioning emergency power supply. Many companies and public institutions, therefore, use emergency generators to remain operational in emergencies.

An Often Overlooked Danger: Fuel Ageing and Contamination

An emergency generator can only operate reliably if both the technology and the fuel are in impeccable condition. However, diesel, petrol, or extra-light heating oil undergo natural ageing processes and can lose quality over time.

Risks Associated with Aged Fuel:

-

Water accumulation in the tank: Condensation can cause moisture to settle at the bottom.

-

Microbial contamination: Bacteria, fungi, and yeasts can proliferate due to water ingress.

-

Deposits from oxidation and polymerisation: Especially biodiesel components (FAME) can cause contamination.

Potential Consequences:

-

Blocked filters and valves

-

Corrosion of fuel lines

-

Damage to injection systems

-

Total failure of the emergency generator

How Often Should Fuel Quality Be Checked?

Depending on the application area of the emergency generator, different inspection cycles apply:

-

Monthly test run: Operators should test the emergency generator under load for about 15 to 60 minutes at least once a month. This ensures that the engine is operational and no deposits are blocking the injection.

-

Annual inspection: In addition to technical maintenance, a laboratory fuel analysis should be conducted to detect contaminants such as water, microorganisms, or chemical ageing early.

-

Starter battery check: The generator's battery is crucial for a quick start in emergencies. An annual check helps prevent capacity losses.

Prevention: The Solution is Fuel Analysis

To ensure a reliable emergency power supply, operators of emergency generators should regularly check their fuel quality. Experts recommend an annual fuel analysis by an accredited laboratory to detect problems early. At AGROLAB GROUP, we offer analyses for diesel, extra-light heating oil, and petrol to operators of emergency generators, companies, and public institutions. Our test results help you manage your fuel storage safely and avoid unplanned outages.

Conclusion: Emergency Generators Are Only as Reliable as Their Fuel

An emergency generator is only a real safeguard against power outages if the stored fuel is in impeccable condition. Regular fuel testing can prevent failures and increase operational safety.

Author: Ing. Petra Führer, I.M.U. GmbH

Further Information

Here you can find more information about our fuel analyses.

Contact

Contact

Contact

Contact Career

Career